Valve-tek Precision Casting Elevates Precision Casting Services with Advanced Mold Flow Analysis Software

Valve-tek Precision Casting Foundry has recently introduced the advanced foundry mold flow analysis software, injecting new momentum into our precision casting services. This technological investment in data simulation not only effectively reduces casting losses caused by air holes but also provides outstanding quality precision cast products for Valve-tek's OEM casting customers in all industrial sectors.

Embracing a New Era of Data Simulation

With 40 years of precision casting experience, Valve-tek Precision Casting has always been committed to excellent casting quality and customer satisfaction. To better meet market changes, we have not only accumulated practical casting experience but also actively invested resources to upgrade inhouse hardware and software technologies. The introduction of mold flow analysis software marks a significant step into a new era of data simulation for us.

Technological Upgrade Addresses Air Hole Issues

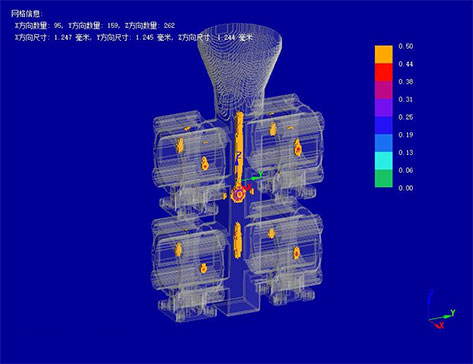

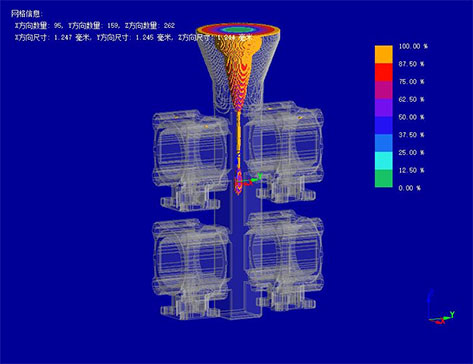

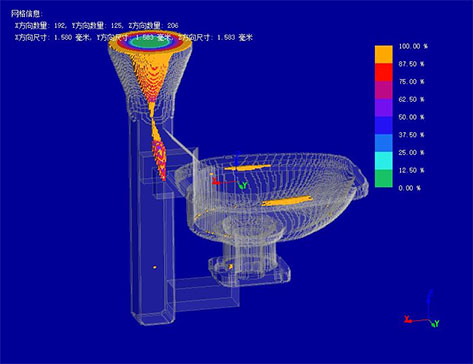

During the investment casting production, air hole issues are a challenge that cannot be ignored, potentially affecting casting quality and even leading to scrapped castings. Through the newly introduced mold flow analysis technology, we can pre-detect the possible locations of air holes, conduct trial mold analyses, and adjust mold designs and casting plans. This not only reduces the defective rate of castings but also significantly enhances product quality.

Efficiency Enhancement and Quality Assurance

The application of mold flow analysis technology not only addresses air hole problems but also predicts and optimizes the manufacturing process before production. This will greatly reduce trial mold costs and time, thereby improving our casting process design and production efficiency, ensuring that each casting product meets the highest standards as our quality principle.

Valve-tek Precision Casting – Committed to Excellence

This investment in technological upgrades reflects Valve-tek Precision Casting's commitment to quality and further strengthens our leading position in the field of precision casting in Taiwan. We will continue to strive, leveraging 40 years of experience as our foundation and strength, integrating cutting-edge software technology to provide our customers with superior casting solutions.

Thank you for your continuous support, and we look forward to ushering in a new era of precision casting together!